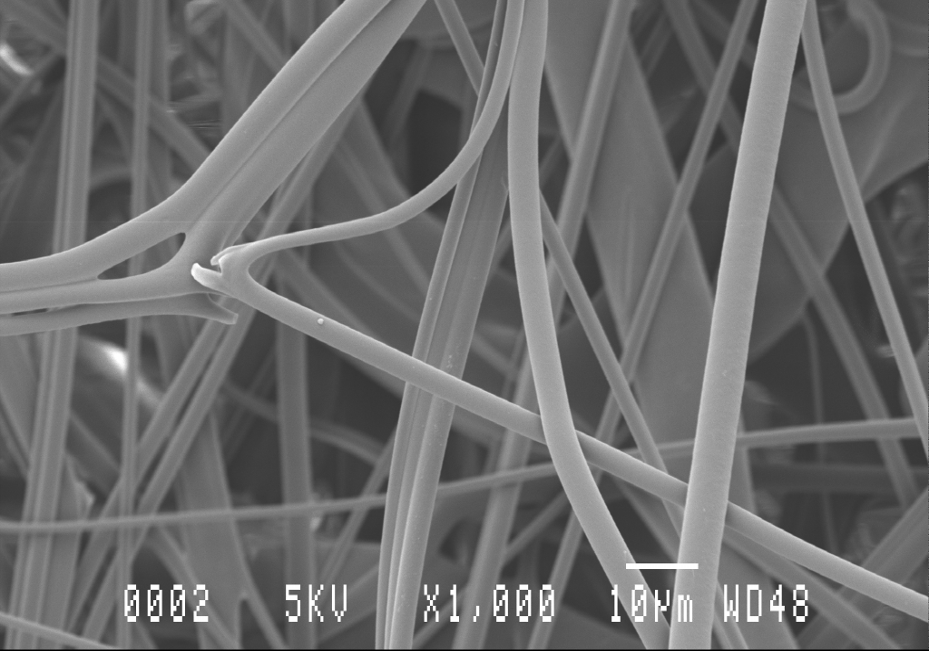

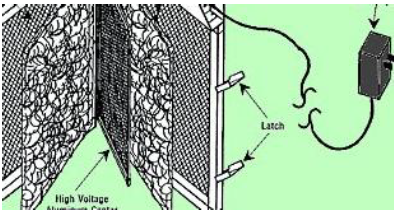

Electrostatically charged media open construction allows loading throughout its depth with minimal airflow and pressure drop change[/vc_column_text][vc_single_image image=”308″ img_size=”full” alignment=”center” css=”.vc_custom_1512985669939{padding-top: 30px !important;}”][vc_column_text]With collaboration the 3M we supply all types of HVAC filters to our clients in the regions.

- Highest absorption in 1 microns particle in primary filter

- Very low pressure drop in secondary filters

- Very high efficiency in PM 2.5 air environment

- Potential energy saving by switching to 3M filters

- Autoroll Filters

- Chemical Filters

- Liquid Filters

- Oil Mist Filters

efficiency ratings.[/vc_column_text][vc_column_text]

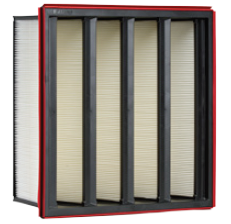

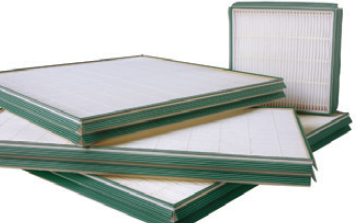

| Filter Name | Filter Type | Initial Pressure Drop @ 492 fpm | ASHRAW Efficiency 52.2: 2007 52.2: 2007 Appendix J | |

|

3M™ Commercial HVAC Filter MERV A15 (Yellow) | V-Bank with Gasket Standard and Reverse Flow | 0.26″ w.g. | MERV 16/ MERV A15  |

|

3M™ Commercial HVAC Filter MERV A14 (Black) | V-Bank with Gasket Standard and Reverse Flow | 0.23″ w.g. | MERV 15/ MERV A14  |

|

3M™ Commercial HVAC Filter MERV A13* (Red) | V-Bank with Gasket Standard and Reverse Flow | 0.21″ w.g. | MERV 14/ MERV A13*  |

|

3M™ Commercial HVAC Filter MERV A13* (Red) | 2″ Mini-Pleat with Gasket | 0.39″ w.g. | MERV 14/ MERV A13*  |

|

3M™ Commercial HVAC Filter MERV A12* (Blue) | 2″ Mini-Pleat with Gasket | 0.37″ w.g. | MERV 14/ MERV A12* |

|

3M™ Commercial HVAC Filter MERV A11 (Orange) | 2″ Mini-Pleat with Gasket | 0.25″ w.g. | MERV 12/ MERV A11 |

|

3M™ Commercial HVAC Filter MERV A8 (Green) | 2″ Mini-Pleat with Gasket | 0.26″ w.g. | MERV 11/ MERV A8 |

|

3M™ Commercial HVAC Filter MERV A12* (Blue) | 2″ Mini-Pleat No Gasket | 0.25″ w.g. | MERV 14/ MERV A12* |

|

3M™ Commercial HVAC Filter MERV A8 (Green) | 2″ Mini-Pleat No Gasket | 0.26″ w.g. | MERV 11/ MERV A8 |

*Important use restriction: This filter must not be used as a primary filter in hospitals and healthcare facilities where a MERV 14 primary filter is required per ASHRAE 170 – 2013. 3M recommends the use of 3M™ Commercial HVAC Filter Products with a minimum rating of MERV A14 or greater.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row full_width=”stretch_row” equal_height=”yes” content_placement=”top” css=”.vc_custom_1512123905652{background-color: #f2f2f2 !important;}”][vc_column][vc_text_separator title=”3M™ High Air Flow (HAF) Air Filters” add_icon=”true”][vc_row_inner][vc_column_inner][vc_column_text]

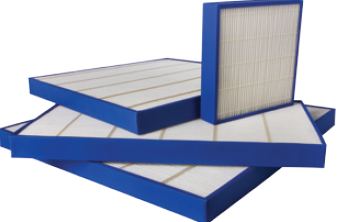

| Filter Name | Filter Type | Initial Pressure Drop @ 492 fpm | ASHRAW Efficiency 52.2: 2007 52.2: 2007 Appendix J | |

|

3M™ High Air Flow (HAF) Air Filters (White) | Frameless, microstructured media | 0.04″ w.g. @ 200 fpm | 52.2: 2007 Arrestance: Up to 50% |

|

3M™ High Air Flow (HAF) Air Filters with Antimicrobial Agent (Green) | Frameless, microstructured media | 0.04″ w.g. @ 200 fpm | 52.2: 2007 Arrestance: Up to 50% |

| Technical Specification | ESSA air filter | 3M A11 Minipleat filter |

| Filtration theory Both type of filters are using electrostatic charges to attract the particles |

|

|

| Input Voltage | 24 VAC | Not applicable as 3M filter need NO electricity. It is permanently electrostatically charge by 3M proprietary technique. |

| Consumption current | Below 10mA | |

| Emission voltage | 3.2 ~ 5.8 KVDC | |

| Electromagnetic Level | No signification reactivity hazard | |

| Ozone Level | Zero ozone emission | |

| Frame Material | Aluminium | Synthetic material with gasket to minimise the air by-pass |

| Filter Media Material | Wax coated Fibre Glass | Melt brown synthetic fibre which is bio-degradable and can discard as general waste. |

| Quality Standard | ISO14000 (compiled) | ISO14000 |

| Test Standard | Ashrae 52.2 Merv 9 (achieved) | Ashrae 52.2 Merv 12

Ashraw 52.2 App J; Merv 11 |

| Particle size (um) | 0.3 | 0.5 | 1 | 5 |

| At air velocity of 2.5m/s (492 fpm) | 10~25% | 20~40% | 50~65% | 95~98% |

| Particle size (um) | 0.3-0.5 | 0.5-1 | 1-5 | 5+ |

| At air velocity of 3.0m/s | 18.1% | 41.4% | 46.8% | 85.7% |

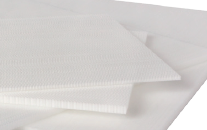

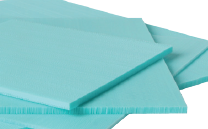

FiltreteTM Air Filter Media Type G

Including G, GS, GSB and GCC

3M Filtrete Type G air filter media is an electret filter media that goes beyond

conventional mechanical capture mechanisms by also using permanent electrostatic charges to remove airborne particles. It is ideal for applications where high efficiency, low pressure drop and high loading are critical and space is at a premium.[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text]

Characteristics:

- Longer life and lower costs because of open construction with high loading

- More economical operation due to low pressure drop with high efficiency

- Permanently charged fibers capture more sub-micron particles than conventional media

- Large selection of basis weights and thickness

- Multitude of framing options

The combination of electrets and open construction provide a low pressure drop with superior efficiency. A lower pressure drop allows the construction of a system with a higher flow rate and more air changes per hour. An alternate choice may be the same airflow but a reduced blower speed and quieter, more energy efficient operation. The overall results, beyond the increase in efficiency, may include longer life, reduced costs and energy savings.[/vc_column_text][/vc_column_inner][/vc_row_inner][vc_single_image image=”285″ img_size=”large” alignment=”center”][vc_single_image image=”286″ img_size=”large” alignment=”center”][vc_row_inner][vc_column_inner width=”1/2″][vc_column_text]

Applications:

Applications include room air purifiers, air conditioners, disc drives, vacuum cleaner exhaust filters, copy machines, printers, electronic equipment and cabin air filtration. This media can also be used in a variety of medical applications including anaesthetic gas/respiratory care, pulmonary

function/spirometry and incubator filters[/vc_column_text][/vc_column_inner][vc_column_inner width=”1/2″][vc_column_text]

Product Selection:

Type G media comes in a large variety of basis weights and constructions to meet all your filtration needs. Basis weights range from 30 to 300 grams per square meter. We can assist you in a custom design of the optimum filter for your application. The graphs at the end of this document provide a good starting point for selection of the best product for your application. Please contact Technical Service for complete information.[/vc_column_text][/vc_column_inner][/vc_row_inner][/vc_column][/vc_row][vc_row full_width=”stretch_row” equal_height=”yes” content_placement=”top” css=”.vc_custom_1512123905652{background-color: #f2f2f2 !important;}”][vc_column][vc_text_separator title=”Type G Constructions” add_icon=”true”][vc_single_image image=”287″ img_size=”large” alignment=”center”][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]

Efficiencies and Pressure Drops:

The plot below and the ones on the following pages show initial efficiencies

and pressure drops for common basis weights of the Type G media at stated flow rates. We can also provide information at the specific flow rate and efficiency needs of your application.[/vc_column_text][vc_single_image image=”288″ img_size=”medium”][/vc_column][vc_column width=”1/2″][vc_column_text]

Framing

Filter frames can range from no frame, to flexible or lightweight frames, to

rigid or heavy duty ones. Please see Filtration Products’ bulletin “Framing

Options” for more information. It can be used as a starting point for

understanding the various options available. Consult with Filtration

Products Technical Service for specific applications.

Temperature and Humidity Resistance:

Type G media resists degradation over time and is able to withstand extremes in temperature and humidity up to 160oF (70oC) and 100% relative

humidity.

Recommended Shelf Life: Two years from date of product manufacture when stored at room temperature conditions of 72oF (22oC) and 50% relative humidity.

Cleaning:

Filters should be replaced rather than cleaned. Filter replacement schedule is

determined by application requirements.[/vc_column_text][/vc_column][/vc_row][vc_row full_width=”stretch_row” equal_height=”yes” content_placement=”top” css=”.vc_custom_1512123905652{background-color: #f2f2f2 !important;}”][vc_column][vc_text_separator title=”Efficiency vs. Particle Size” add_icon=”true”][vc_single_image image=”293″ img_size=”full” alignment=”center”][vc_single_image image=”291″ img_size=”full” alignment=”center”][vc_single_image image=”292″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row full_width=”stretch_row” equal_height=”yes” content_placement=”top”][vc_column][vc_text_separator title=”Pressure Drop vs. Face Velocity” add_icon=”true”][vc_single_image image=”294″ img_size=”full” alignment=”center”][/vc_column][/vc_row]